In the realm of construction and infrastructure development, the efficiency and quality of steel beam fabrication play a pivotal role in determining the overall success of a project. Recent reports from the American Institute of Steel Construction (AISC) indicate that improper fabrication techniques can lead to significant cost overruns, with inefficiencies potentially escalating project costs by up to 20%. The steel construction sector is increasingly prioritizing optimized fabrication processes to enhance structural integrity while minimizing waste.

Industry expert Dr. Michael Thompson, a leading figure in structural engineering, emphasizes the critical need for innovation in steel beam fabrication. He states, “By integrating advanced technologies such as automation and modular design into our fabrication processes, we can not only improve quality but also deliver projects faster and more economically.” This perspective underlines the significant benefits that can be realized through the adoption of cutting-edge practices in the steel beam fabrication industry.

Ultimately, optimizing steel beam fabrication is not just about efficiency; it's about ensuring safety and sustainability in construction. As industry standards evolve and demand for high-quality, durable structures increases, the focus on refining fabrication methods will be essential in meeting the challenges of modern engineering and construction.

Steel beam fabrication is a critical process in the construction industry, and understanding the techniques involved can significantly enhance both the quality and efficiency of the output. The primary method of fabrication starts with the selection of high-grade steel, ensuring the material possesses the necessary strength and durability for structural applications. Once the appropriate steel is chosen, it undergoes cutting, welding, and shaping processes. Techniques such as plasma cutting and laser cutting offer precision in cutting the steel to the required dimensions, minimizing waste and enhancing the overall quality of the finished product.

In addition to cutting methods, welding techniques play a crucial role in steel beam assembly. Common welding processes like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) provide strong and reliable joints, which are essential for maintaining structural integrity. Furthermore, incorporating modern fabrication technologies, such as computer numerical control (CNC) machines, can streamline operations and improve accuracy, leading to faster production times. Regular inspections during the fabrication process are also vital, allowing for the early detection of potential issues and ensuring that the beams meet both safety standards and project specifications. By mastering these fundamental techniques, fabricators can optimize their operations for both quality and efficiency, resulting in robust steel structures tailored to meet various engineering demands.

| Fabrication Technique | Description | Efficiency Rating (%) | Quality Rating (%) | Common Applications |

|---|---|---|---|---|

| Welded Beam Fabrication | Joining steel sections using welding processes. | 85 | 90 | Structural Frames, Bridges |

| Bolted Beam Fabrication | Using bolts for securing steel sections together. | 75 | 85 | Heavy Machinery, Industrial Buildings |

| Laser Cutting | Utilizing laser technology for cutting steel beams. | 90 | 95 | Precision Structures, Architectural Elements |

| CNC Machining | Computer-controlled fabrication for precise dimensions. | 95 | 92 | Custom Fabrications, Signage |

| Manual Cutting and Welding | Traditional methods using tools for cutting and joining. | 60 | 75 | Repair Works, Small Projects |

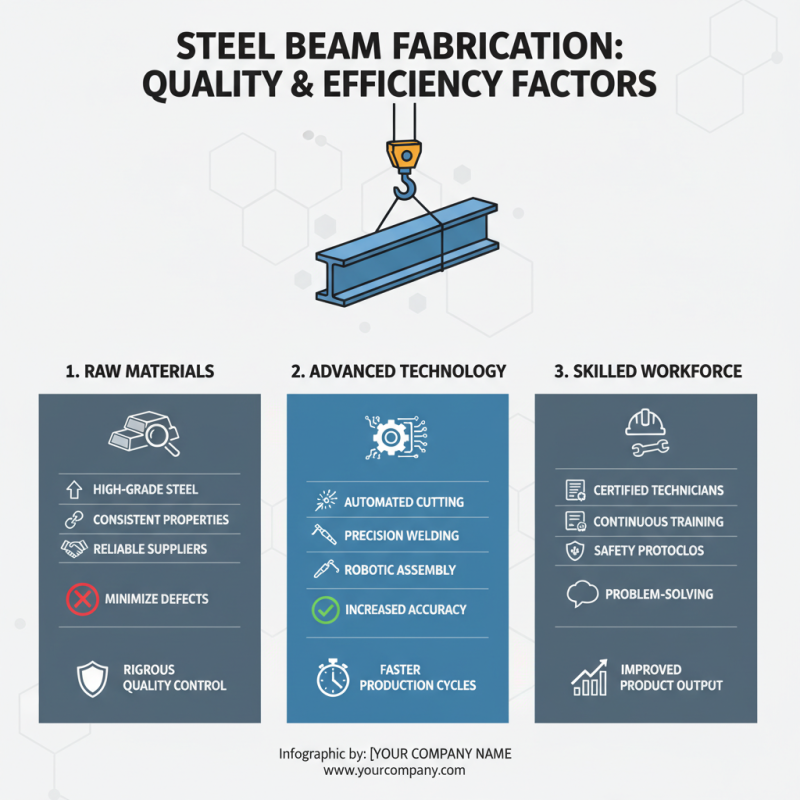

In the steel beam fabrication industry, several key factors significantly impact both quality and efficiency. One of the primary considerations is the choice of raw materials. High-grade steel with consistent properties ensures that the beams produced possess the desired strength and durability. Additionally, the sourcing of materials from reliable suppliers can minimize defects and variations, leading to a smoother production process. Implementing rigorous quality control measures during the material selection stage can prevent costly rework later in the fabrication process.

Another vital factor is the optimization of manufacturing processes. Techniques such as automation and advanced cutting technologies can greatly enhance efficiency by reducing manual labor and minimizing human error. Incorporating real-time monitoring systems helps maintain the desired quality standards throughout the production cycle. Furthermore, employee training plays a crucial role in ensuring that workers are well-versed in the latest techniques and safety protocols, ultimately contributing to higher productivity and superior quality in the final products. By addressing these critical areas, steel beam fabrication operations can achieve a seamless balance between quality and efficiency.

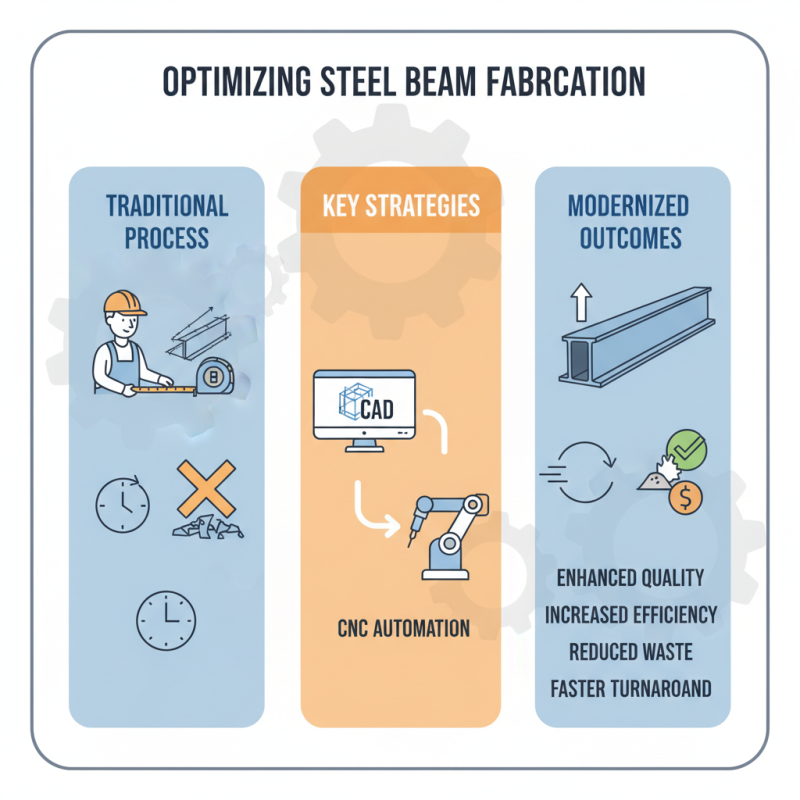

Optimizing the fabrication process of steel beams not only enhances quality but also improves overall efficiency. One effective strategy is to implement advanced technology and automation throughout the production workflow. Utilizing computer-aided design (CAD) and computer numerical control (CNC) machines minimizes human error and increases precision. This, in turn, leads to reduced material waste and faster turnaround times.

Tips: Regular maintenance of machinery is crucial to prevent unexpected breakdowns that can halt production. Schedule routine checks and calibrations to ensure equipment operates at peak performance.

Another approach to streamline the fabrication process is to adopt lean manufacturing principles. By identifying and eliminating non-value-added activities, teams can maximize their productivity. This could involve reorganizing workspace layouts or improving communication channels to enhance collaboration between different departments.

Tips: Foster a culture of continuous improvement by encouraging team members to provide feedback on processes. Small adjustments can lead to significant gains in efficiency over time.

Quality control measures are crucial in steel beam manufacturing to ensure that the final products meet industry standards and customer expectations. One fundamental aspect of quality control is the implementation of rigorous inspection processes at various stages of production. This includes initial material inspections to verify the quality of raw steel and adherence to specified grades and compositions. By employing non-destructive testing methods such as ultrasonic testing and magnetic particle inspection, manufacturers can detect internal and surface flaws that could compromise the structural integrity of steel beams.

Another essential quality control measure is the use of well-defined fabrication procedures and guidelines. Standard operating procedures (SOPs) should be established for welding, cutting, and assembling steel beams. These procedures must be meticulously followed to ensure uniformity and quality across all products. Regular training sessions for workers on these SOPs not only enhance their skills but also foster a culture of quality awareness within the manufacturing facility. Additionally, maintaining accurate records of productivity and quality metrics allows for continuous improvement and helps identify trends or recurring issues that may need addressing, thereby enhancing overall efficiency in the fabrication process.

Advancements in technology are playing a pivotal role in optimizing steel beam fabrication, enhancing both quality and efficiency in construction projects. One significant development is the use of advanced manufacturing techniques, such as automated robotic welding and precision cutting tools, which have been shown to improve accuracy and reduce waste. According to the American Institute of Steel Construction, utilizing automation in fabrication can lead to up to a 30% reduction in production times, enabling faster project completion without compromising on structural integrity.

Moreover, the integration of Building Information Modeling (BIM) has transformed how steel beams are designed and fabricated. BIM allows for detailed visualization and data management throughout the fabrication process, facilitating better communication between design and manufacturing teams. A report from McKinsey & Company highlights that projects employing BIM saw a 15% increase in efficiency and a substantial reduction in error rates, leading to enhanced overall project quality. As these technologies continue to evolve, their adoption in the steel fabrication industry promises to drive further improvements, positioning companies to meet the growing demands of modern construction and infrastructure projects.