The process of steel girder fabrication plays a crucial role in the construction and manufacturing industries, serving as the backbone for various structures, from bridges to high-rise buildings. According to the American Institute of Steel Construction, the construction industry is projected to grow significantly, with an expected market size reaching $1.15 trillion by 2025. Steel girders are essential in this growth, providing durability, strength, and cost-effectiveness for structural applications. The fabrication process involves several key techniques, including cutting, welding, and assembly, each contributing to the overall efficiency and effectiveness of the final product.

The advantages of steel girder fabrication are manifold, not only enhancing the performance of various infrastructural projects but also influencing sustainability through reduced waste and energy savings. Industry reports have highlighted that the use of steel in construction can lead to a 50% reduction in energy consumption compared to traditional materials, demonstrating the environmental benefits of this fabrication process. As demand for robust and resilient structures increases, understanding the intricacies of the steel girder fabrication process becomes essential for engineers and architects aiming to meet contemporary construction challenges. Through meticulous practices and advancements in technology, the steel girder fabrication process continues to evolve, paving the way for innovative designs and sustainable construction practices.

Understanding the fabrication process of steel girders is essential for ensuring structural integrity and efficiency in construction projects. Steel girders, which serve as the primary support for buildings and bridges, undergo various fabrication techniques that transform raw steel into robust structural components. The process typically begins with detailed design and planning, followed by the cutting, shaping, and assembling of steel sections. Advanced welding and fastening methods are deployed to create strong, durable connections that can withstand significant loads.

Tips: When embarking on a steel girder fabrication project, be sure to have accurate specifications and working drawings. This will aid not only in precision during the fabrication process but also in minimizing material waste and reducing costs. Collaborating with skilled fabricators ensures that the final product meets all safety standards and design requirements.

Another crucial aspect is the implementation of quality control measures throughout the fabrication process. Regular inspections and testing of welds and materials can prevent potential structural failures. Employing modern technologies like computer-aided design (CAD) can enhance precision and streamline the fabrication workflow, ultimately improving project timelines and outcomes.

The steel girder fabrication process plays a pivotal role in modern construction projects, offering numerous benefits that enhance structural integrity and efficiency. One of the primary advantages is the strength-to-weight ratio of steel, making it ideal for supporting heavy loads while minimizing overall weight. This characteristic not only facilitates more extensive designs but also reduces the need for excessive foundational support, ultimately leading to cost savings.

Additionally, the fabrication process ensures precision and quality control. Advanced techniques such as computer-aided design (CAD) and automated welding lead to higher accuracy in the dimensions and connections of steel girders, enhancing the reliability of the entire structure. These techniques allow for off-site fabrication, which can significantly decrease construction timelines and minimize disruptions at the worksite.

**Tips:** To maximize the benefits of steel girder fabrication, ensure close collaboration with fabricators during the design phase. Proper planning and communication can lead to innovative solutions and optimize the construction workflow. Furthermore, consider investing in training for on-site teams to handle steel connections effectively, as this can greatly impact the performance of the assembled structures.

| Dimension | Details |

|---|---|

| Material | High-Strength Steel |

| Fabrication Techniques | Welding, Cutting, Bending |

| Key Benefits | Durability, Strength, Cost-Effectiveness |

| Applications | Bridges, Buildings, Infrastructure |

| Sustainability | Recyclable Material |

| Lead Time | Varies from weeks to months |

| Quality Control | Inspections, Tests, Certifications |

The steel girder fabrication process is a critical component in the construction of robust structures, and it involves several essential techniques that ensure precision and durability. One important technique is cutting, which can be carried out using various methods such as plasma cutting or laser cutting. These techniques allow for the creation of complex shapes and dimensions, ensuring that each girder meets specific project requirements. Additionally, the use of advanced Computer Numerical Control (CNC) machinery enhances cutting precision, significantly reducing waste and improving overall efficiency in the fabrication process.

Another key technique in steel girder fabrication is welding. It is vital for joining different sections of steel girders securely. Various welding methods, including MIG and TIG welding, can be employed to create strong, lasting connections that withstand heavy loads. Furthermore, the use of automated welding processes ensures consistency and reduces the risk of human error. Additionally, thorough inspection and testing, such as non-destructive testing (NDT), are integral to this phase, guaranteeing that each weld meets the necessary safety and quality standards. Overall, these essential techniques not only streamline the fabrication process but also enhance the structural integrity of the final product.

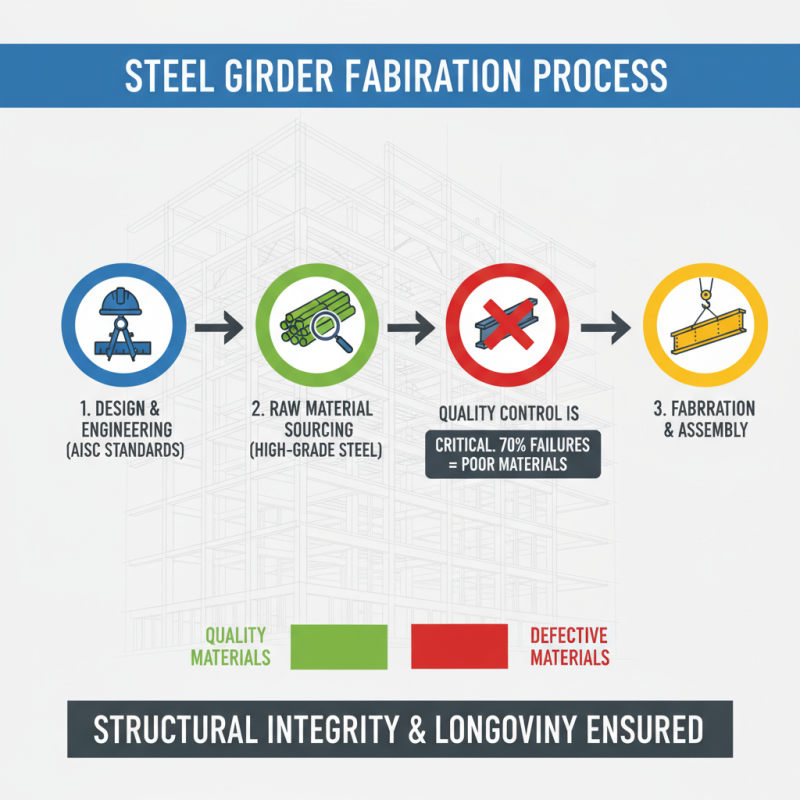

The steel girder fabrication process is a critical aspect of construction that ensures the structural integrity and longevity of buildings and infrastructure. This process typically starts with detailed designs and drawings that adhere to industry standards, such as those set by the American Institute of Steel Construction (AISC). Following design approval, raw materials are sourced, primarily high-grade steel. This phase emphasizes quality control, as using superior steel directly impacts the durability and safety of the final product. According to industry reports, around 70% of structural failures can be traced back to poor material selection and manufacturing defects.

Once materials are on-site, the fabrication process begins with cutting the steel to specified lengths, followed by processes such as welding, drilling, and grinding. Each step is executed with precision; for instance, automated cutting techniques can reduce waste by up to 20%. After the pieces are fabricated, they are subjected to rigorous inspections to ensure compliance with all safety and quality standards. It is essential to maintain thorough documentation during this process, as well, as it helps in traceability and accountability.

Tips: Ensure that your fabrication team is well-trained in the latest techniques and safety measures. Regular inspections during the fabrication process can significantly reduce the risk of rework and delays. Lastly, consider implementing advanced technologies, such as BIM (Building Information Modeling), to enhance efficiency and collaboration between teams. Implementing these strategies can lead to a more streamlined fabrication process and ultimately a successful construction project.

Quality control is a critical aspect of the steel girder fabrication process, ensuring that every component meets the stringent standards required for structural integrity and safety. One of the key measures implemented during fabrication includes detailed inspections at each stage of the process. This begins with the examination of raw materials, where the steel's chemical composition and mechanical properties are verified to ensure they comply with specifications. Throughout the fabrication timeline, various non-destructive testing techniques, such as ultrasonic tests and magnetic particle inspections, are utilized to detect any internal flaws or surface irregularities that could compromise the girder's performance.

In addition to inspections, the fabrication process incorporates a systematic approach to documentation and traceability. Each girder is assigned a unique identification number that links it to detailed records of the manufacturing process, including material certifications and testing reports. This transparency not only facilitates compliance with industry standards but also allows for efficient tracking and resolution of any issues that may arise post-fabrication. Implementing these quality control measures not only enhances the reliability of the final product but also contributes to overall operational efficiency, ensuring that projects remain on schedule and within budget while upholding safety and performance standards.