The steel fabrication industry is witnessing a significant transformation driven by advancements in technology and automation. According to a report by ResearchAndMarkets, the global steel fabrication market is expected to reach USD 207.9 billion by 2026, growing at a CAGR of 5.6% from 2021. This growth is attributed to the increasing demand for steel in construction and manufacturing sectors, which in turn propels the need for high-quality steel fabrication machines.

Selecting the right steel fabrication machine is crucial for businesses aiming to enhance efficiency, increase productivity, and maintain high-quality standards. The evolution of these machines, which now integrate smart technologies and innovative design features, plays a pivotal role in streamlining production processes. Advanced steel fabrication machines enable precision in tasks such as cutting, welding, and bending, thus ensuring a robust output that meets the modern demands of various industries.

As companies strive for competitiveness in a rapidly evolving market, understanding the specifications and capabilities of different steel fabrication machines becomes imperative. This guide aims to explore the key factors to consider when choosing the best equipment for your projects, ensuring that they align with your operational objectives and contribute to your long-term success in the steel fabrication landscape.

When selecting the ideal steel fabrication machines for your projects, it is crucial to assess your specific needs and the capabilities of the equipment.

First, consider the types of materials and thicknesses you will be working with.

Different machines cater to various steel grades and dimensions, so ensuring compatibility with your materials will lead to greater efficiency and reduced waste.

Additionally, think about the complexity of your projects; will you require machines that can handle intricate designs, or are simpler cuts sufficient?

Understanding your project requirements allows you to make an informed decision on the type of machinery that will best serve your operations.

Moreover, evaluate the features and technology offered by various steel fabrication machines.

Some may focus on speed and efficiency, while others emphasize precision and versatility.

Advanced machines equipped with automation and computer numerical control (CNC) capabilities can significantly improve production rates and reduce human error, which is vital for high-stakes projects.

Furthermore, consider the weight and size of the machines—this impacts the installation, space requirement, and mobility within your workspace.

By taking these factors into account, you can select the right equipment that enhances productivity and aligns with your operational goals.

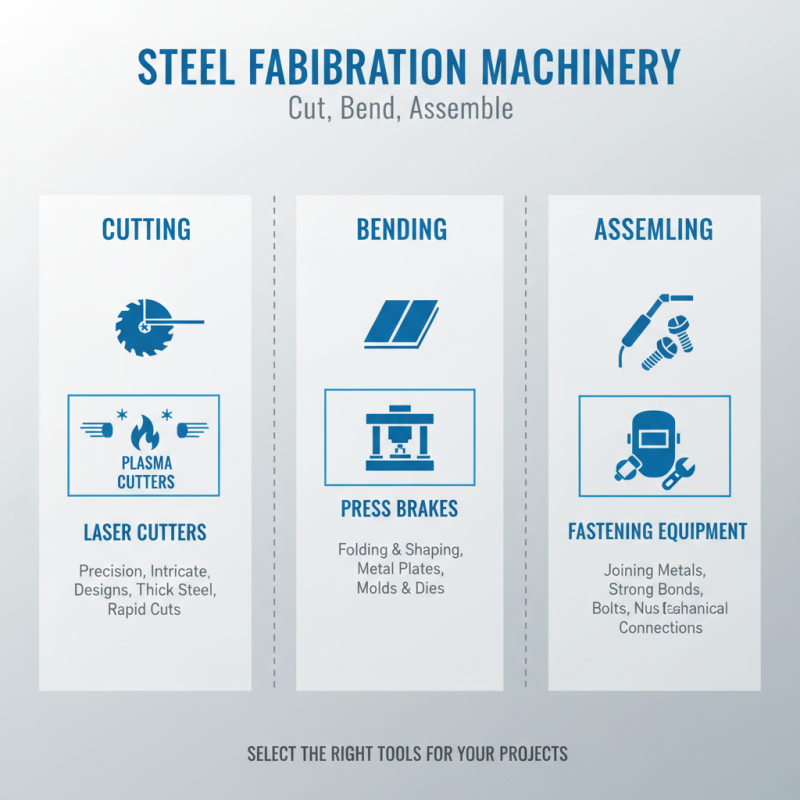

When it comes to steel fabrication, understanding the different types of machines available is crucial for selecting the right tools for your projects. Steel fabrication machinery can be broadly categorized into cutting, bending, and assembling machines. Cutting machines, such as laser cutters and plasma cutters, are essential for producing precise cuts in various steel thicknesses. Laser cutters offer accuracy and efficiency, making them ideal for intricate designs, while plasma cutters are better suited for thicker materials due to their rapid cutting speeds.

Bending machines, like press brakes and roll benders, are integral in shaping steel into desired angles and curves. Press brakes use hydraulic pressure to create sharp bends in metal sheets, and they come in a range of sizes to accommodate different material dimensions. Roll benders, on the other hand, are used for creating rounded shapes and are particularly valuable in applications requiring circular or tubular forms. Understanding the specific applications and capabilities of these machines can significantly enhance productivity in any fabrication project.

Finally, assembling machines such as welders and riveters play an essential role in joining steel pieces together. Welding machines, including MIG and TIG welders, provide versatility for various types of joints and materials, ensuring a strong and durable assembly. Riveting machines, although less common now, are still used in specific applications requiring mechanical fastening. Familiarity with these fabrication machines allows professionals to select the best options tailored to their project's requirements, ensuring efficiency and quality in the final product.

When selecting steel fabrication equipment, it's crucial to consider several key features that can significantly impact the efficiency and quality of your projects. A recent industry report suggests that over 40% of fabrication errors stem from the use of inferior machinery, emphasizing the importance of investing in high-quality tools. One of the primary features to look for is the machine's precision capabilities. Advanced CNC (Computer Numerical Control) machines offer repeatability within microns, which is essential for producing parts that meet stringent specifications. Additionally, machines equipped with adaptive technology can adjust parameters in real-time, enhancing both speed and accuracy in the fabrication process.

Another important aspect is the versatility of the equipment. Fabrication processes such as cutting, welding, and bending require machines that can handle multiple functions. Data from a market analysis indicates that facilities with multi-functional machines report a 30% increase in production efficiency, as they reduce the need for multiple standalone devices. Lastly, ease of operation and maintenance should not be overlooked. Intuitive interfaces and readily available technical support can drastically decrease downtime and improve workforce productivity, leading to a smoother operation overall in steel fabrication projects.

| Machine Type | Key Features | Specifications | Typical Applications | Price Range |

|---|---|---|---|---|

| CNC Plasma Cutters | High precision cutting, fast processing speed, easy programming. | Up to 200A plasma, cutting thickness: up to 1 inch. | Metal fabrication, construction, artistic projects. | $25,000 - $80,000 |

| Laser Cutters | High accuracy, versatile material capability, minimal edge burn. | 1000W to 4000W, cutting thickness: up to 0.5 inch. | Automotive, aerospace, electronics. | $30,000 - $150,000 |

| Sheet Metal Benders | Precision bending, adjustable angles, easy operation. | Capacity: up to 10 tons, bending length: 4-10 feet. | HVAC, cabinetry, custom metal work. | $15,000 - $50,000 |

| Welding Machines | Versatile welding processes, portable, user-friendly. | MIG, TIG, stick capabilities; amperage range: 20-300A. | Fabrication, repairs, construction. | $500 - $5,000 |

| Metal Forming Machines | Efficient forming processes, high production rates, multiple die sets. | Capacity: up to 50 tons, stroke length adjustable. | Automotive, structural components, appliance manufacturing. | $20,000 - $100,000 |

The steel fabrication industry is witnessing a transformative shift driven by technological advancements and innovative equipment solutions. As the demand for precision and efficiency rises, manufacturers are increasingly incorporating automation into their fabrication processes. This not only streamlines operations but also enhances productivity by minimizing manual intervention. Newer machines equipped with advanced software for design and manufacturing allow for greater flexibility, enabling fabricators to adapt quickly to changing project requirements and complex designs.

Market trends indicate a growing emphasis on sustainability in steel fabrication as companies prioritize eco-friendly practices. Innovations such as energy-efficient machines and methods that reduce waste are becoming integral to the industry's modernization efforts. Furthermore, the integration of smart technology, like IoT-enabled devices, offers real-time monitoring and analytics, allowing for optimized performance and predictive maintenance. As businesses seek to remain competitive, these advancements are essential in improving overall operational efficiency and reducing costs, positioning steel fabrication as a forward-thinking sector ready to meet the challenges of the future.

When selecting a steel fabrication machine, cost analysis plays a pivotal role in determining the most economical choice for your projects. Understanding the total cost of ownership, which includes purchase price, maintenance costs, operational expenses, and potential downtime, is essential for making an informed decision. A machine that appears less expensive upfront may incur higher costs over time due to inefficiencies or repairs, ultimately impacting project budgets and timelines.

Moreover, it's crucial to compare the features and technology of various machines to gauge their long-term value. Investing in a more advanced machine with greater capabilities may seem costly initially, but its efficiency and productivity enhancements can lead to significant savings in labor costs and material waste in the long run. Additionally, consider the flexibility of the machine to handle diverse projects; a versatile machine can adapt to different tasks without the need for multiple investments, thus optimizing budget allocation and reducing overall expenditures.