The steel and fabrication industry is on the brink of a transformative era. Experts emphasize the need for innovative approaches to tackle ongoing challenges. John Smith, a renowned figure in the field, remarked, “Innovation is crucial for our survival.” His words resonate deeply within a sector that must adapt or risk obsolescence.

As we look toward 2026, advancements in technology and sustainable practices are reshaping the landscape. Steel production must become greener. Techniques like recycling and alternative materials are gaining traction. The shift is not just necessary; it’s vital for future generations. However, not all innovations are flawless. Companies are often trapped in traditional mindsets and resist change.

The demand for efficiency and sustainability is becoming more pressing. Yet, the industry struggles with implementation. Skills gaps remain a challenge. Reflections on past failures can provide valuable lessons. Embracing new ideas while acknowledging these flaws may lead to a brighter future for the steel and fabrication industry. The journey ahead holds both promise and uncertainty.

The steel and fabrication industry is evolving rapidly. As we look ahead to 2026, several trends are emerging. One significant trend is the shift towards sustainable practices. Many companies are adopting eco-friendly methods to reduce their carbon footprint. Investments in green technology are becoming crucial. For example, more manufacturing facilities are exploring ways to utilize renewable energy sources.

Another notable change is the advancement in automation. Robotics and AI are transforming production processes. Automation helps improve efficiency and reduce human error. However, the reliance on technology poses challenges. Workers may face job displacement, and there are concerns about training gaps. The industry must ensure that employees adapt to these innovations.

Moreover, supply chain resilience is becoming a priority. Recent global disruptions have highlighted vulnerabilities. Companies are rethinking their sourcing strategies. They aim to establish more localized supply chains. Yet, this shift may lead to higher costs. Balancing cost and resilience will be a critical challenge moving forward. The industry must navigate these complexities to thrive in the coming years.

Innovation in the steel and fabrication industry is crucial. Advances in steel production processes are reshaping the landscape. One notable innovation is the use of automation and robotics. These technologies streamline production, but they also create new challenges. Workers may face job displacement. Balancing efficiency with workforce stability is necessary.

Another important shift is the adoption of sustainable practices. Eco-friendly methods reduce emissions and energy usage. Recycling steel is gaining traction. However, not all facilities have made the switch. Many still rely on traditional methods that harm the environment. It’s vital to encourage industry-wide changes.

Digital technologies are also transforming processes. Data analytics offer insights for optimization. Predictive maintenance reduces downtime. Yet, many companies struggle with implementation. Integrating new systems can be complex. There is a need for training and adaptation. The path towards innovation is filled with obstacles, but the vision for a more efficient future is bright.

Sustainability has become a key focus in the steel and fabrication industry. Many companies are adopting eco-friendly practices. These advancements aim to reduce carbon footprints and enhance energy efficiency. Using renewable energy for production is gaining traction. This shift helps minimize reliance on fossil fuels.

Implementing circular economy principles is another significant trend. This involves recycling steel and other materials rather than discarding them. It's an excellent way to decrease waste. Companies must rethink their supply chains to adopt these practices.

**Tips:** Consider investing in energy-efficient machinery. Adopt a comprehensive recycling program for scrap materials. Engage employees in sustainability training to foster a greener mindset. These actions may involve some costs upfront, but the long-term benefits can be substantial. Embracing sustainable innovations is essential for progress, yet challenges remain.

This chart illustrates the advancements in sustainable practices within the steel and fabrication industry from 2023 to 2026. The data highlights the percentage of innovations focused on energy efficiency, recycling initiatives, and environmentally friendly materials.

Emerging technologies are reshaping the steel and fabrication industry. Automation is often at the forefront. Robots now handle repetitive tasks. This reduces human error and speeds up production. However, reliance on automation can lead to job displacement. Industries must find a balance.

Additive manufacturing is another innovation. This technology creates parts layer by layer. It offers design flexibility and reduces material waste. However, it can be costly to implement fully. Companies must carefully consider investments in this area. Not every firm may find it feasible.

Data analytics plays a crucial role in improving efficiency. Real-time monitoring allows companies to predict failures. This proactive approach minimizes downtime. Yet, many organizations struggle to integrate these systems. The challenge lies in training staff and adapting workflows. Embracing these changes won’t happen overnight. Careful planning is essential for success in this evolving landscape.

| Innovation | Description | Expected Impact | Implementation Year |

|---|---|---|---|

| Advanced Robotics | Integration of AI-driven robots for precise fabrication tasks. | Increased efficiency and reduced labor costs. | 2026 |

| 3D Metal Printing | Use of additive manufacturing to create complex metal parts. | Shorter production times and reduced material waste. | 2026 |

| Smart Sensors | Sensors embedded in equipment to monitor performance and predict failures. | Enhanced maintenance and reduced downtime. | 2025 |

| Green Steel Production | Methods to produce steel with lower carbon emissions, using renewable energy. | Reduced environmental impact and improved sustainability. | 2026 |

| Digital Twin Technology | Virtual models of physical assets to optimize operations. | Improved decision-making and operational efficiency. | 2026 |

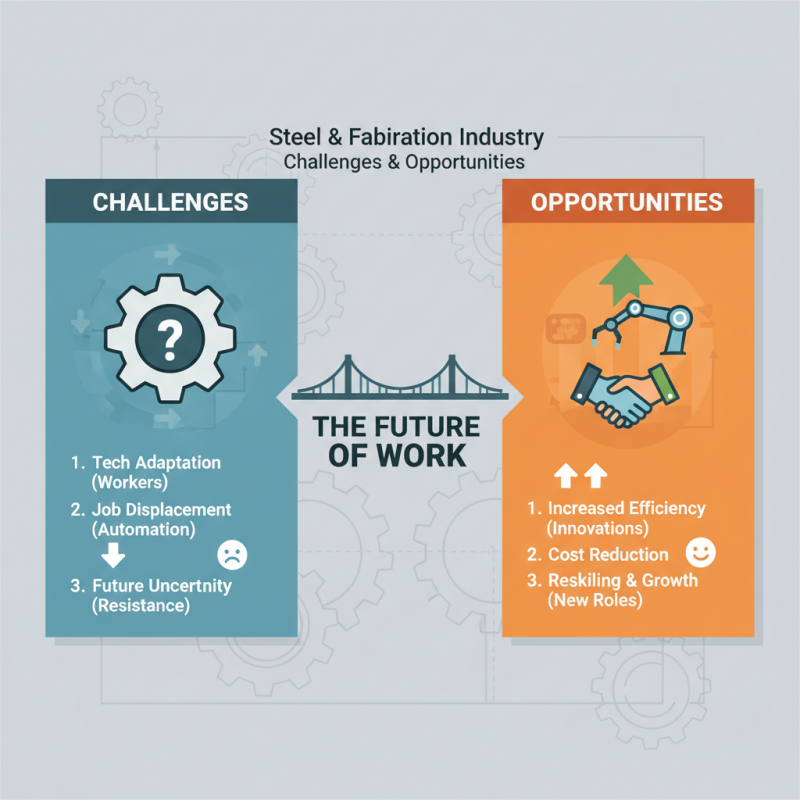

The steel and fabrication industry faces numerous challenges and opportunities in the coming years. Innovations in technology aim to increase efficiency but also require adaptation by workers. Automation can reduce costs but may displace jobs, leading to a need for reskilling. Many workers feel uncertain about their future roles, which could create resistance to new methods.

Sustainability remains a critical focus. The industry is under pressure to reduce carbon emissions and waste. Innovative practices, like using alternative materials, could help meet these goals. However, the transition is often slow and requires significant investment. Smaller companies may struggle to keep pace with larger firms that have more resources.

As new technologies emerge, the industry must stay flexible. Embracing digital tools is essential for competitiveness. However, not all innovations yield immediate results. There may be unexpected failures along the way. Learning from these experiences can help shape better solutions. Resilience and adaptability will be key as the steel and fabrication sector navigates its future.