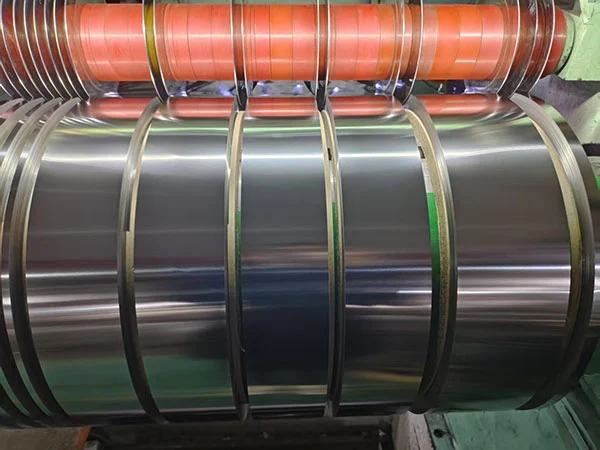

Ningbo Jilian Steel Co., Ltd. is among China's largest manufacturers of 0cr21al6nb FeCrAl Alloy Coil. We specialize in producing 1.4767/Cral6/0Cr21Al6, 1.4725/Cral4/0Cr18Al4, and 0Cr15Al5. With our experience in alloy R&D, we continuously improve the alloys we utilize, winning the favor of manufacturers worldwide in related industries.

0cr21al6nb FeCrAl alloy coil is a special alloy material with iron, chromium and aluminum as the main elements, and a certain amount of niobium (Nb) added. It is manufactured through a unique alloy formula design and advanced production technology, combining the good mechanical properties of iron-based alloys with the excellent high-temperature performance brought by chromium and aluminum elements. The addition of niobium further improves the comprehensive performance of the alloy, making it show unique application value in many industrial fields.

| GRADE | Chemical Composition | |||||

| Cr | AI | Nb | AI | Fe | P | |

| 0Cr21AI6Nb | 21.0-23.0 | 5.0-7.0 | 0.5 | 5.4475 | Moderate Amount | Moderate Amount |

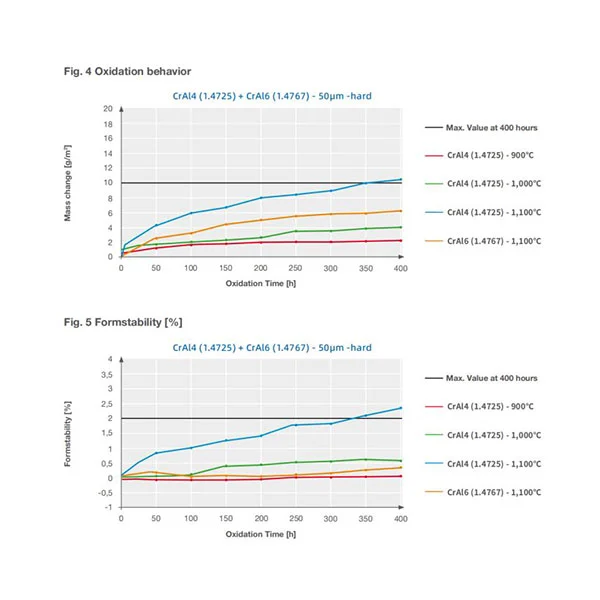

In a high temperature environment, a dense and stable aluminum oxide protective film will quickly form on the surface of 0cr21al6nb FeCrAl alloy coil . This oxide film can effectively prevent oxygen from further reacting with the alloy matrix, thereby greatly slowing down the oxidation rate of the alloy at high temperatures and extending its service life. For example, in an environment where the continuous working temperature reaches 1200°C, the alloy coil can still maintain good oxidation resistance, and its oxidation resistance can be increased several times compared to ordinary steel.

The addition of niobium significantly enhances the strength and stability of the alloy at high temperatures. Even in a long-term high temperature environment, 0cr21al6nb FeCrAl alloy coil can maintain high mechanical properties and is not prone to deformation and fracture. This enables it to operate reliably under working conditions of high temperature and certain loads, meeting the needs of various complex working conditions.

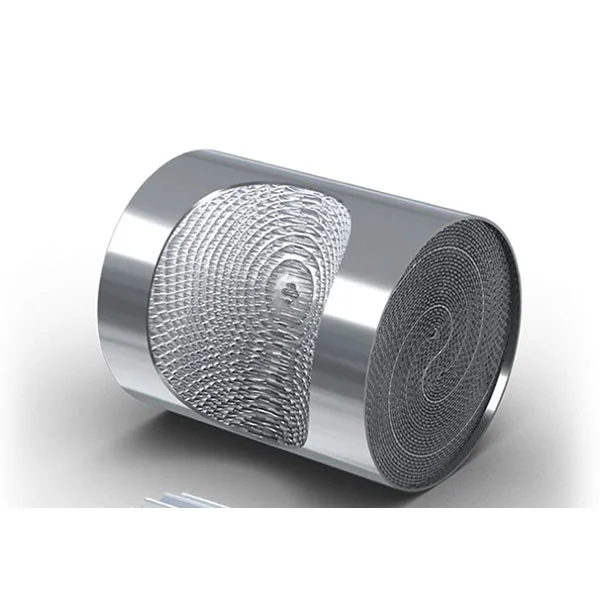

0cr21al6nb FeCrAl alloy coil has a relatively low and stable resistivity, which can effectively convert electrical energy into thermal energy during the power-on heating process, reducing energy loss during transmission. This characteristic makes it an ideal material for manufacturing various electric heating elements, such as heating wires for industrial electric furnaces and heating elements in household appliances, which can improve the energy efficiency of electric heating equipment and reduce operating costs.

0cr21al6nb FeCrAl alloy coil has good adaptability in both cold and hot processing. It can be made into products of various shapes and sizes through rolling, drawing, stamping and other processing techniques to meet the personalized needs of different users. At the same time, during the processing, the alloy is not prone to defects such as cracks, which ensures the quality and performance stability of the product.

0cr21al6nb FeCrAl alloy coil is a high-performance alloy material, mainly composed of iron, chromium, aluminum and other elements. Maximum temperatures are as follows: CrAl4/1.4725 up to 1.000°C, CrAl6/1.4767 up to 1.200°C.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods (0cr21al6nb FeCrAl alloy coil ) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...