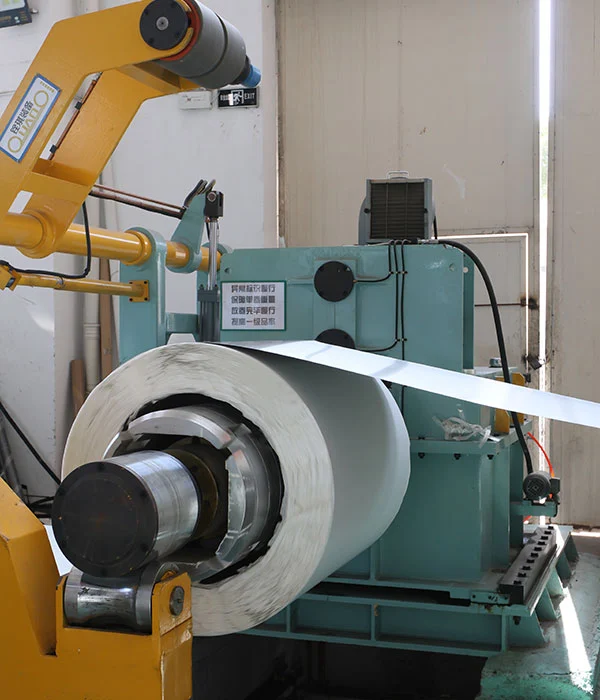

Ningbo Jilian Steel Co., Ltd is a leading supplier of 310s High Temperature Alloy Strip in China. The thicknesses Jilian Steel produce is 0.01mm to 3.0mm, and 1219mm max width. We warmly welcome business partners from international markets to collaborate sincerely for mutual success.

310s high temperature alloy strip is a high-performance austenitic chromium-nickel stainless steel material. With its unique chemical composition and excellent physical properties, it plays an important role in many industrial fields. Its chemical composition contains a high proportion of chromium and nickel, which makes it exhibit excellent oxidation resistance and corrosion resistance in high temperature environments. Its melting point is as high as 1400℃. Even at a high temperature of 1150℃, it can still maintain good strength and plasticity. The dense oxide film formed on the surface effectively blocks the erosion of corrosive media.

| GRADE | Chemical Composition | ||||||

| C | Si | Mn | P | S | Ni | Cr | |

| % | % | % | % | % | % | % | |

| 310S | ≤0.08 | ≤1.05 | ≤2.00 | ≤0.045 | ≤0.030 | 19.00/22.00 | 24.00/26.00 |

In terms of processing and welding, 310s high temperature alloy strip also performs well. It can be processed and formed by a variety of processes such as forging, rolling, and welding. Commonly used welding materials such as ER-310 welding wire or A402 welding rod can ensure the welding quality. At the same time, reasonable parameter control during the welding process can avoid the degradation of material performance and ensure its reliability in subsequent use.

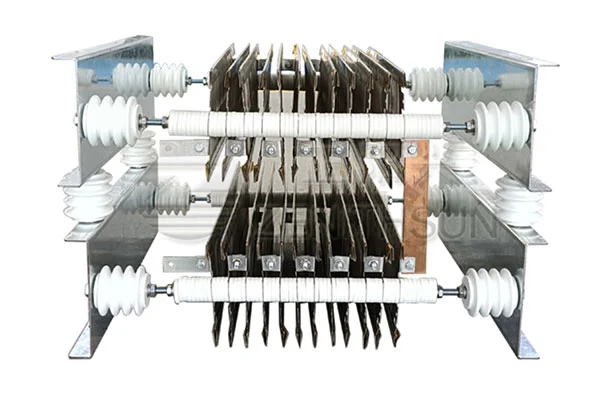

The application range of 310s high temperature alloy strip is extremely wide. In the petrochemical industry, it is used to manufacture key equipment such as high-temperature furnace tubes, heat exchangers, and heaters. These equipment need to operate stably in an environment of high temperature, high pressure, and corrosive media. The performance of 310s high temperature alloy strip perfectly meets this demand. In the power industry, it is used for superheaters, reheaters and other components of boilers to ensure the safety and durability of power equipment under high temperature conditions. In addition, it is also widely used in aerospace engine parts, automobile exhaust systems, high-temperature equipment for food processing, and the internal structure of environmental protection equipment. Whether it is in extremely high-temperature aircraft engines or common automobile exhaust pipes in daily life, 310s high temperature alloy strip can provide reliable protection with its excellent performance.

In short, 310s high temperature alloy strip is indispensable in many high-end industrial applications due to its high temperature resistance, corrosion resistance, easy processing and welding, and is an important material that is indispensable to modern industry.

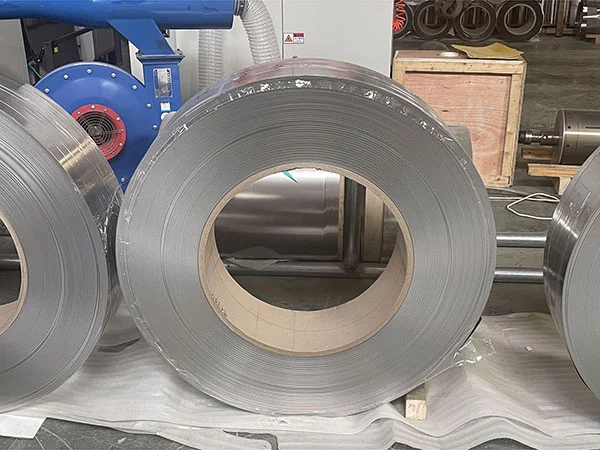

The 310s high temperature alloy strip has high accuracy, with thickness tolerances as tight as +/-0.002mm. It has 2B, BA, 2BA and more surface finish. The surface we produce are flawless, scratch-free, which it is best choice for applications that demand the highest quality.

As for packaging details, there are standard packaging (waterproof paper and steel belt packing) and wooden box packaging, as well as customized packaging solutions.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods ( 310s high temperature alloy strip) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...